Water ingress investigations are a large portion of our Tank Trouble Tuesday features, but they can be complicated to pinpoint, as was the case in the fiberglass tank featured below.

Tuesday, December 18, 2018

Tank Trouble Tuesday

Labels:

Fiberglass,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Tuesday, December 11, 2018

Tank Trouble Tuesday

Operators of fueling sites with fiberglass tanks that were installed after the EPA 40 CFR part 280 UST regulations were launched in 1988 are now looking at a tank population that is between 20 and 30 years old.

Prudent operational practices suggest that it's time to evaluate those tanks and fueling systems – and get solid answers to some really important questions: What's the condition of the tanks? Can you get by with them for another 5 or 10 years? Do any need to be repaired or upgraded? Do any need to be replaced now? And if so, how do you prioritize them?

These can be tough questions to get good answers to. But those answers are important. If you could get a good look at the conditions inside your tanks, what would you see?

Check out our Aging Fiberglass UST Assessment Program to see more.

Tuesday, December 4, 2018

Tank Trouble Tuesday

As every tank owner knows, underground storage tanks are major responsibilities. As the tanks age or change hands, UST owners may find it increasingly difficult to know the true conditions of their tanks.

TankCam visual inspections are the perfect tool to determining what's happening inside your tanks, including identifying the cause of a 50 gallon/day leak, as in this fiberglass tank.

Tuesday, November 27, 2018

Tank Trouble Tuesday

TankCam inspections are an excellent tool to determine the extent of a problem observed in your UST, as in the case of the flaking fiberglass tank shown below.

Tuesday, November 20, 2018

Tank Trouble Tuesday

Tank Trouble Tuesday was started to show the industry rarely seen images from the inside of underground storage tanks. Some of the images show severe problems like corrosion, cracking, blistering and delamination.

This Thanksgiving week, however, Tanknology gives "tanks" for all of the USTs in the United States that are in good condition: like the fiberglass tanks shown above, or the 30 year old steel tank shown below.

Tuesday, November 13, 2018

Tank Trouble Tuesday

TankCam inspections are one of the many varied services that Tanknology offers.

Encounter a problem? Looking to do preventative maintenance at your fueling station?

Check out our full list of services.

Encounter a problem? Looking to do preventative maintenance at your fueling station?

Check out our full list of services.

Labels:

Fiberglass,

Tank Trouble Tuesday,

TankCam,

VacuTect,

Water Ingress

Tuesday, November 6, 2018

Tank Trouble Tuesday

Today marks the 100th Edition of Tank Trouble Tuesday

We thank those of you who have been with us since the beginning, welcome you if you've just now joined us, and look forward to continuing to bring you our most exciting TankCam footage.

Today, we're celebrating the Best of the Worst in Tank Trouble Tuesday with some of our favorite clips of degredation in the video below.

Curious about our previous 99 posts?

Tuesday, October 30, 2018

Tank Trouble Tuesday

Do you have a monster in your tank?

Monsters don't always hide under your bed or in your closet. Changes in the way we make and blend gasoline and diesel has accelerated the occurrence of corrosion, cracking, blistering, and delamination in underground storage tanks. Conditions that could soon lead to problems with fueling and potentially exposing you to a significant leak. Don't look now, but you have a monster growing in your tank!

TankCam inspections by Tanknology reveal problems, big or small, in underground storage tanks. TankCam inspections can also be combined with Tanknology's FuelPure and TankClean services to ensure a tank free of sludge and debris, including monsters.

Can't get enough of monsters and slime in USTs? Trick-or-treat for an Apple Watch by signing up for Tank Trouble Tuesday emails at this link, or by texting TANKTROUBLE to 228-28.

Tuesday, October 23, 2018

Tank Trouble Tuesday

We frequently utilize our TankCam service to pinpoint a water ingress, check out more investigation stories on this page of our blog.

Labels:

corrosion,

Steel,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Tuesday, October 16, 2018

Tank Trouble Tuesday

The sludge in your tank -- even after a tank cleaning -- can be dizzying! Check out the Texas tank below, following cleaning by a third party.

As an alternative method -- that will be sure to verify if sludge is left behind -- our TankClean method utilizes our TankCam technology before, during, and after cleaning the tank. We only clean the parts that need to be cleaned, minimizing waste water, and provide you with the images to show you your actual tank conditions.

As an alternative method -- that will be sure to verify if sludge is left behind -- our TankClean method utilizes our TankCam technology before, during, and after cleaning the tank. We only clean the parts that need to be cleaned, minimizing waste water, and provide you with the images to show you your actual tank conditions.

Tank Trouble Tuesday

This Illinois fiberglass tank exhibited peeling on the tank top.

Visit our website to learn more about the applications of a TankCam inspection.

Tuesday, October 2, 2018

Tank Trouble Tuesday

Corrosion in USTs is a hot topic, but do you know what it looks like?

This week's Tank Trouble Tuesday offers a view of corrosion on an ATG riser for a tank containing premium fuel.

Check out this early edition of Tank Trouble Tuesday for a view of a corroded riser from a ULSD tank.

This week's Tank Trouble Tuesday offers a view of corrosion on an ATG riser for a tank containing premium fuel.

Check out this early edition of Tank Trouble Tuesday for a view of a corroded riser from a ULSD tank.

Labels:

corrosion,

Fiberglass,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Tuesday, September 25, 2018

Tank Trouble Tuesday

As every tank owner knows, underground

storage tanks are major responsibilities. As the tanks age or change hands, UST owners may find it increasingly

difficult to know the true conditions of their tanks.

TankCam visual inspections are the perfect tool to determining what's happening inside your tanks, including identifying ingresses, cracks, and deflection, as observed in a Hawaii tank.

Friday, September 21, 2018

National Tanks Conference 2018

The 26th National Tanks Conference & Exposition, hosted by The New England Interstate Water Pollution Control Commission (NEIWPCC), was held on Sept. 11-13 in Louisville, Kentucky.

The 26th National Tanks Conference & Exposition, hosted by The New England Interstate Water Pollution Control Commission (NEIWPCC), was held on Sept. 11-13 in Louisville, Kentucky.Federal and state regulators, manufacturers, environmental firms, fuel marketers, testing companies and industry associations attended the conference to learn what stakeholders are thinking about, what they are talking about and what may be ahead. Here are the highlights, as reported in the PEI TulsaLetter.

Sump Testing. State regulators continue to wrestle with sump testing options. The hydrostatic testing method recommended in PEI/RP1200: Recommended Practices for the Testing and Verification of Spill, Overfill, Leak Detection and Secondary Containment Equipment at UST Facilities and endorsed by the U.S. Environmental Protection Agency (EPA) in the 2015 federal underground storage tank (UST) regulations is or will be recognized in most states. When alternative low-water-level test methods are allowed, they often are subject to requirements beyond those in the technical compendium accompanying the 2015 federal rule. New Mexico, for example, allows low-water-level testing in only limited circumstances. The PEI/RP1200 hydrostatic test must be used at the time of sump installation and on every fourth three-year inspection (i.e., every 12 years). States also are implementing penalties for owners and operators who inappropriately tamper with the sensor used in low-level sump testing.

Aging UST Systems. Regulators are growing more concerned about the risks associated with tanks that have reached the end of their 30-year warranty. Several regulators and industry professionals wanted to discuss a suggestion PEI made recently in the PEI Journal and the L.U.S.T.Line : that states should work together closely to compile and aggregate data on their UST systems. Comparable data on tank age, type and the frequency and source of failures nationwide would increase the industry’s understanding of the risks associated with older tanks—and encourage better strategies for reducing those risks.

Internal Corrosion. Every regulator reported increased internal corrosion in gasoline and diesel UST systems. One conference presenter emphasized how temperatures above 76 degrees can accelerate the bacterial growth that is behind most corrosion. Expect more studies on the correlation between temperature and corrosion.

Emergency Generator Day Tanks. These tanks are gaining greater regulatory attention as their numbers increase and their risks become more apparent. In many cases, day tanks have no secondary containment, no overfill protection, are filled automatically and lack adequate venting. PEI expects increased state regulation of day tanks in the future, including greater reliance on the procedures in PEI/RP1400: Recommended Practices for the Design and Installation of Fueling Systems for Emergency Generators.

Thursday, September 20, 2018

Tanknology at 30!

Tuesday, September 18, 2018

Tank Trouble Tuesday

We utilized our TankCam to confirm a water ingress in an Illinois double-walled fiberglass tank by visually verifying drops of liquid falling from the manway around the STP shaft.

Want to hear more about things we've found in tanks? Sign up for Tank Trouble Tuesday emails!

Want to hear more about things we've found in tanks? Sign up for Tank Trouble Tuesday emails!

Labels:

Fiberglass,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Tuesday, September 11, 2018

Tank Trouble Tuesday

Signs of water ingress and a failed tightness test were two indicators of major deficiencies in this Michigan tank. TankCam inspections offer a unique perspective of visually identifying the problem, with no need for costly excavation or dangerous manned entry.

Labels:

Fiberglass,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Thursday, September 6, 2018

National Tanks Conference Panel to Feature Tanknology’s Hoffman

Brad Hoffman, Vice President of Engineering for Tanknology, will participate in a panel discussion

on Fuel Compatibility at the 2018 National Tanks Conference and Exposition. The panel will convene on Tuesday, September 11 at 10:30 a.m. Also participating in the panel are Tiffany Yee, Environmental Engineer, Arizona DEQ and Ryan Haerer, Program Analyst, U.S. EPA OUST. The panel will be moderated by Jonathan McRae, Supervisor, UST/LUST, Nevada DEP.

The 26th National Tanks Conference & Exposition will be held September 11-13, 2018, at the Galt House Hotel in Louisville, Kentucky.

Hoffman has over 30 years of experience with Underground Storage Tank systems, testing and compliance. He holds a B.S. in Mechanical Engineering from the University of Tulsa and currently serves as Vice President of Engineering and R&D for Austin-based Tanknology, where he develops equipment for testing, inspecting, and cleaning tanks, and manages the safety, quality, and training programs. Hoffman is active on several PEI and API committees, and holds a Class A Engineering License in California as well as several state contractor licenses. He is a former field engineer and program manager for Exxon.

Based in Tanknology’s Austin Headquarters, Hoffman can be reached at bhoffman@tanknology.com or at (512) 451-6334.

Tuesday, September 4, 2018

Tank Trouble Tuesday

TankCam inspections often identify problems in tanks, but inspections have multiple pro-active applications as well.

One example is the easy identification of the tank material -- steel, fiberglass, etc., as in the Illinois tanks featured below.

One example is the easy identification of the tank material -- steel, fiberglass, etc., as in the Illinois tanks featured below.

Tuesday, August 28, 2018

Tank Trouble Tuesday

Have your tanks been showing signs of rust and sludge? If so, do you know if that's indicative of a larger problem in your tank?

Our TankCam inspections are a quick and cost effective way to find out what's happening inside your tank, and identify both minor and major issues.

Thursday, August 23, 2018

In 2006 Tanknology tested its one-millionth tank. It took less than 12 years to reach 2 million. #TanknologyAt30

Tuesday, August 21, 2018

Tank Trouble Tuesday

Labels:

corrosion,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Thursday, August 16, 2018

Today, Tanknology provides environmental compliance testing and inspection services at more than 50,000 petroleum fueling and storage facilities per year, offering more than 20 compliance-related service offerings. #TanknologyAt30

Tuesday, August 14, 2018

Tank Trouble Tuesday

Fuel drops happen frequently, but an inside perspective is rare! Site operators in South Carolina had their double-walled fiberglass tank cleaned, then requested a video of the fuel drop of diesel fuel, which we were able to provide with our TankCam HD inspection service.

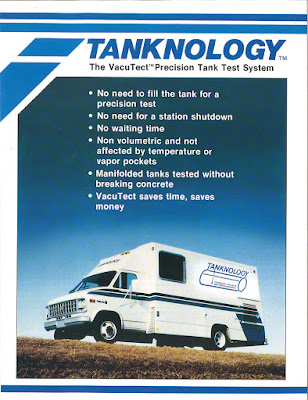

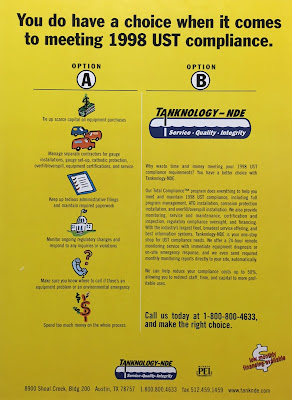

Wednesday, August 8, 2018

Tanknology's VacuTect® Tank Testing System was introduced in 1988, the year the company was founded. VacuTect is certified to test tanks at virtually any product level. Since 1988, more than one million VacuTect tests have been performed around the world. #TanknologyAt30

Tuesday, August 7, 2018

Tank Trouble Tuesday

The inspection of this Texas tank confirmed the presence of residual liquid and sludge, as well as debris such as ATG floats on the tank bottom.

Labels:

corrosion,

Steel,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Tuesday, July 31, 2018

Tank Trouble Tuesday

The crack in this Hawaii tank was notable-- extending almost all the way around the seam.

Read more in the GIF below, or get Tank Trouble Tuesday delivered to your email inbox.

Read more in the GIF below, or get Tank Trouble Tuesday delivered to your email inbox.

Friday, July 27, 2018

11 Weeks Until the UST Revised Regulation Deadline

• UST owners and operators in Indian country and in states, territories, and the District of Columbia (collectively referred to as states) without UST state program approval (SPA) must meet remaining 2015 federal UST requirements on or before the FEDERAL deadlines.

Are you ready!? October 13, 2018, which is only 11 weeks away, is the deadline for meeting the remaining underground storage tank (UST) requirements in the 2015 revised UST regulation. Key takeaways about the compliance deadline are:

• States with state program approval must re-apply by October 13, 2018 if they wish to retain program approval status.

• UST owners and operators in states with program approval must continue to follow their states’ requirements, which may be different from the 2015 federal UST requirements. State requirements can be found here.

I acknowledge and appreciate the dedicated effort and remarkable work by state, territorial, and tribal UST programs; owners and operators; testers; and others in the UST community who have made significant progress in meeting the October compliance deadline. Although some may still have more to do, collectively we have made much progress to date. For more information about the October compliance deadline, see EPA’s UST website https://www.epa.gov/ust/revising-underground-storage-tank-regulations-revisions-existing-requirements-and-new#compliance.

I acknowledge and appreciate the dedicated effort and remarkable work by state, territorial, and tribal UST programs; owners and operators; testers; and others in the UST community who have made significant progress in meeting the October compliance deadline. Although some may still have more to do, collectively we have made much progress to date. For more information about the October compliance deadline, see EPA’s UST website https://www.epa.gov/ust/revising-underground-storage-tank-regulations-revisions-existing-requirements-and-new#compliance.

As always, I am extremely grateful for your attention to and help with keeping our environment safe from petroleum UST releases. Please share your ideas or feedback on what EPA can do to help everyone achieve compliance; contact me or Tony Raia (raia.anthony@epa.gov or 202-566-1021) of my staff.

I acknowledge and appreciate the dedicated effort and remarkable work by state, territorial, and tribal UST programs; owners and operators; testers; and others in the UST community who have made significant progress in meeting the October compliance deadline. Although some may still have more to do, collectively we have made much progress to date. For more information about the October compliance deadline, see EPA’s UST website.

As always, I am extremely grateful for your attention to and help with keeping our environment safe from petroleum UST releases. Please share your ideas or feedback on what EPA can do to help everyone achieve compliance; contact me or Tony Raia (raia.anthony@epa.gov or 202-566-1021) of my staff.

Carolyn Hoskinson

Hoskinson.carolyn@epa.gov

202-564-2564

Thursday, July 26, 2018

Since 1988, Tanknology has tested more than 2 million tanks and provide associated compliance services at more than 50,000 sites each year. #TanknologyAt30 #TheToddFergusonHashtag

Tuesday, July 24, 2018

Tank Trouble Tuesday

A customer in Indiana had found gravel in the filters of their steel tank, read more about our visual inspection of the tank in the GIF below.

Visit our website to learn more about TankCam inspections.

Tuesday, July 17, 2018

Tank Trouble Tuesday

This Pennsylvania tank exhibited deflection and multiple cracks -- the likely source of the water intrusion detected. Check out the GIF below to read the details.

Tank Trouble Tuesday is now available as an email!

Sign up here or by texting TANKTROUBLE to 22828.

Thursday, July 12, 2018

We pride ourselves on the individual attention we provide to our partners. Since our founding in 1988, Tanknology has grown to become the largest provider of testing and inspection services in the world. Yet we remain committed to the success of our partners, no matter their size or location. #TanknologyAt30

We pride ourselves on the individual attention we provide to our partners. Since our founding in 1988, Tanknology has grown to become the largest provider of testing and inspection services in the world. Yet we remain committed to the success of our partners, no matter their size or location. #TanknologyAt30

Tuesday, July 10, 2018

Tank Trouble Tuesday

Kerosene tanks, though often smaller than standard tanks at a service station and less frequently used, are susceptible to similar problems as standard fueling tanks. TankCam inspections are useful for inspecting these tanks as well.

Thursday, July 5, 2018

Tanknology's VacuTect® Tank Testing System was introduced in 1988, the year the company was founded. VacuTect is certified to test tanks at virtually any product level. Since 1988, more than one million VacuTect tests have been performed around the world. #TanknologyAt30 #ThrowbackThursday

Tuesday, July 3, 2018

Tank Trouble Tuesday

We are now sharing Tank Trouble Tuesday direct to your email inbox!

Sign up here or by texting TANKTROUBLE to 22828.

You can still find each edition here on our blog or social media pages.

Tuesday, June 26, 2018

Tank Trouble Tuesday

Site operators in South Carolina requested a TankCam HD inspection of their diesel tank to evaluate its overall condition following a recent tank cleaning. Portions of the tank appeared to have been cleaned, but other portions still exhibited a build-up of sludge and residue.

Tuesday, June 19, 2018

Tank Trouble Tuesday

Site operators in Florida reported that their tanks were taking on water, and the TankCam inspection revealed several cracks and active ingresses in both tanks.

TankCam inspections are a cost-effective strategy for determining the source of an ingress in your UST. You can find all water ingresses featured on Tank Trouble Tuesday at this link.

TankCam inspections are a cost-effective strategy for determining the source of an ingress in your UST. You can find all water ingresses featured on Tank Trouble Tuesday at this link.

Labels:

Fiberglass,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Tuesday, June 12, 2018

Tank Trouble Tuesday

If your tank lining failed, would you know? A TankCam inspection is a valuable tool in evaluating the condition of your UST, including the lining and overall tank condition.

Thursday, June 7, 2018

STS ProTec Eliminates Sump Corrosion

Tanknology is proud to introduce STS ProTec, a sump corrosion treatment and prevention program that allows site owners to prevent environmental contamination and costly component replacement by reconditioning and repairing sumps affected by corrosion.

|

| Before and After Documentation of Sump Conditions |

An STS ProTec treatment renders each sump, not only clear of corrosion, but fully resistant to further contamination. The process uses market-leading technology that meets Underwriters Laboratory and Steel Tank Institute standards.

The technology provides outstanding resistance to cracking, abrasion, impact and deformation over a wide temperature range and allows coated sump components to endure exposure to a wide range of conditions and chemicals. The process does not require a 30, 60 or 90-day reapplication.

Each STS ProTec project is backed by a Five Year Limited Warranty covering product and labor.

Tuesday, June 5, 2018

Tank Trouble Tuesday

Does your UST have recurring water ingress problems? If so, are you wondering what steps to take to fix the issue? Identifying the source of the ingress is one of many services we offer.

A TankCam visual inspection often locates the source of the ingress, and also offers an overview of your tank conditions and any potential degradation. If the water ingress is less obvious, like in the Illinois tank below, our expert technicians follow up and test other tank components to identify the issue.

Labels:

Fiberglass,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Tuesday, May 29, 2018

Tank Trouble Tuesday

TankCam inspections are often requested due to issues like water ingresses, but may lead to the detection of other issues like the drop tube and ball float placed too high in the tank.

Read more about the inspection of this Illinois tank in the GIF below.

Labels:

Fiberglass,

Tank Trouble Tuesday,

TankCam,

Water Ingress

Wednesday, May 23, 2018

Steel Tanks and Fuel Compatibility

The National Research Energy Laboratory, NREL, contacted STI staff recently about studies pertaining to another developing fuel additive to gasoline, isobutanol, and the current downstream fueling infrastructure. Based on what I have read, isobutanol has many parallels to ethanol and is acceptable as an alternative gasoline blend additive in that it increases oxygenates to burn the fuel with few unwanted emissions, while also increasing octane.

Automobile manufacturers are interested in higher octane fuels due to increased efficiency as it burns in motors. Higher engine efficiency can result in less energy loss as the vehicle consumes the fuel, resulting in higher mileage. The United States government has set some very hefty goals for vehicle mileage in the years ahead, and auto manufacturers and the US Department of Energy are researching the additives that will be the best fit with gasoline to increase octane, mileage, and its feasibility.

Automobile manufacturers are interested in higher octane fuels due to increased efficiency as it burns in motors. Higher engine efficiency can result in less energy loss as the vehicle consumes the fuel, resulting in higher mileage. The United States government has set some very hefty goals for vehicle mileage in the years ahead, and auto manufacturers and the US Department of Energy are researching the additives that will be the best fit with gasoline to increase octane, mileage, and its feasibility. Of course, new fuel additives also raise other questions and issues. Is the additive compatible with today’s fuel infrastructure? Is it easily transported? Will the fuel create new issues downstream at the petroleum marketers’ dispensing systems or with emissions from vehicles? For example, the downstream market segment has experienced non-anticipated consequences from sulfur removal from diesel in storage. Refineries produce ULSD to comply with EPA air quality requirements and ASTM fuel quality requirements, yet as the fuel gets transported and stored in other locations, additives are used, water can get absorbed, and microbial activity can occur. Fugitive emissions from equipment operating in sumps installed atop UST’s with ethanol blended gasoline coupled with condensation, has also created random non-anticipated consequences.

Of course, new fuel additives also raise other questions and issues. Is the additive compatible with today’s fuel infrastructure? Is it easily transported? Will the fuel create new issues downstream at the petroleum marketers’ dispensing systems or with emissions from vehicles? For example, the downstream market segment has experienced non-anticipated consequences from sulfur removal from diesel in storage. Refineries produce ULSD to comply with EPA air quality requirements and ASTM fuel quality requirements, yet as the fuel gets transported and stored in other locations, additives are used, water can get absorbed, and microbial activity can occur. Fugitive emissions from equipment operating in sumps installed atop UST’s with ethanol blended gasoline coupled with condensation, has also created random non-anticipated consequences. Engines today require cleaner fuels, less and smaller particulates can be present in fuel. The tolerance for water in today’s fuel storage has become a more significant issue. Hence, the insides of tanks have now become a common focus point for petroleum marketers and their service providers. Maintenance and monitoring and removal of water is paramount to today’s motor vehicle fuel system and back-up power systems. A whole new industry of service providers that did not exist 10 or 15 years ago have formed – fuel polishers, tank cleaners, biocide treatment providers, and internal inspection contractors.

The steel tank industry tracks performance via third party warranty and environmental impairment insurance required of its technology licensees in the United States. Today’s USLD systems experience random, surface corrosion on internal tank metallic components, such as pumps, fill lines, ball vent valves, etc. It sometimes is seen on the tank ullage space itself, even on metal flanges and manways in non-metallic tanks. Yet claim history of underground steel tank manufacturers has not shown an increase in steel tank failures from this phenomenon. Paid warranty claim rate was 0.044% over STICO Mutual’s first 20 years of providing fabricators (building to STI tank specifications) with warranty insurance or 44 tanks per 100,000 tank population.

States, on the other hand, are also worried about tank performance, but more so with aging tanks. A recent study by eight states participating in an ASTSWMO study, indicated that over 50% of its UST’s were over 20 years old, and of single wall construction.

The Arizona Department of Environmental Quality has had recent concerns of aging underground tank performance. They hired Tanknology to use their camera technology to investigate condition of 79 underground storage tanks, 41 diesel and 38 gasoline, located at schools in 21 cities and 7 counties.

Grading the 66 FRP tanks and 13 steel tanks, based on these videos, involved using an A through E grade, similar to grading scales often used in our education system.

Scores were given based on the fuel stored, and a separate set of scores based on the tank material.

Scores were given based on the fuel stored, and a separate set of scores based on the tank material.Since the turn of the century, the biodiesel market has developed, and grown into a billion gallon industry. Since ethanol has been in common use for over 30 years, and even goes back to the days of the Model A, biodiesel remains one of the most significant new additives. Will isobutane become the next? In 2008, STI hired Southwest Research Institute to perform a corrosion study on biodiesel, both with and without water, finding steel to be compatible.

Now isobutanol is coming into the marketplace as a fuel enhancement, or as an alternative to ethanol. Oak Ridge Laboratories, to no surprise, found steel to be compatible with isobutanol.

The full ADEQ presentation from the STI/SPFA Annual Meeting can be found here.

Editors note: This article originally appeared in the May 2018 STI Tank Talk Newsletter. The original article can be found here.

Tuesday, May 22, 2018

Tank Trouble Tuesday

Star cracks, also called spider cracks, are typically caused by impact to the tank walls during installation. If found on the tank bottom they may have been caused by the impact of a dropped object.

Tuesday, May 15, 2018

Tank Trouble Tuesday

Many tank operators know that sediment and sludge is a recurring problem in their USTs, but do you know what it can look like?

Operators in New York noted that sludge build-up and other deficiencies on their fiberglass tanks caused venting issues which led to the TankCam inspection below.

Subscribe to:

Posts (Atom)